What Is a Blind bolt & What Is It Used For?

Blind Bolt US | 6th August 2020

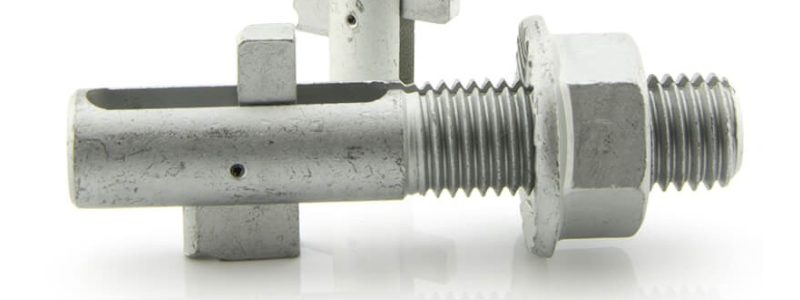

Blind Bolt

If you’re looking for a structural fastener that matches the strength of rivets and welds but is infinitely more adaptable then you’ve found it, and it’s called a blind bolt. Structural fasteners of this kind play a vital role in putting together structures like bridges and buildings by making it possible to join steel to steel in plates or girders. This blog looks into blind bolts, explaining what they are and exactly how you can use them.

What is a Blind bolt?

The name ‘blind bolt’ helps to explain what it can do. It can create a fastening through pre-drilled holes when access is only available from one side, such as when the side completing the lock is hidden inside a girder.

Simplicity is the key to a blind bolt, which consist of just a steel pin, a collar and a sleeve. Tighten the sleeve and you’ll create a pressure which collapses the expander on the hidden side of the fastening. At the same time, on the visible side of the bolt, the sleeve collapses to create a seal. Blind bolts create a connection which matches longevity with strength, but just as appealing is the fact that they are incredibly easy to install and inspect. That’s why they play such a vital role in the construction sector – holding together the steel girders upon which buildings depend.

What Is A Blind Bolt Used For?

On many occasions, restricted access means that using rivets or hex bolts is out of the question, and blind bolts were developed to deal with that exact problem. The effectiveness of the blind bolt solution means that, for decades, they’ve been the first choice for restricted access work in sectors like manufacturing, construction and repair work.

Choosing the Correct Blind Bolt

Choosing the right blind bolt means matching its’ size and strength to the task in hand. Getting this calculation just right means considering a number of factors, such as the following:

Strength and Tensile Strength

The strength of the blind bolt refers to the strength of the fastening it creates. The grip, on the other hand, describes the total thickness of the materials being fastened together. The grip length of the bolt is a vital measurement, and represents the distance from the surface of the underhead to the first thread of the pin shaft. This distance needs to be a fraction smaller than the grip itself.

The tensile strength required depends upon the application for which the blind bolt is being used, meaning it’s vital to choose a bolt with the tensile strength and shear resistance demanded by that application. In general terms, the shear resistance of a bolt refers to the maximum load that can be applied to the axis of a fastener at a right angle before the bolt fractures.

Choosing the correct tensile strength and shear resistance is vital. Get it wrong and the bolts you use will be too narrow or made of the wrong material. This will result in a bond which might initially be strong but which simply won’t last. Any bolt which fails to match the design specifications will suffer damage and wear and tear much more quickly than a bolt which meets these requirements. The end result of this will be much more money having to be spent.

Vibration Resistance

Many applications involve constant vibration and, unlike some other bolts, this won’t loosen blind bolts. This makes them the ideal choice for any high impact sector in which vibration plays a large part, such as bridge construction, shipbuilding, mining and manufacturing.

Corrosion

Blind bolts are the perfect solution for more corrosive environments, thanks to the range of materials from which they are constructed. These materials include alloy steel for the stem, zinc-plated carbon steel for the collars and black oxide for the sleeves. Making the right choice of materials is vitally important, particularly in sectors such as shipbuilding, where the bolt in question is likely to be exposed to highly corrosive seawater. If you’re building ships then you’ll want to use highly corrosion resistant materials such as A4 Stainless steel, in order to guarantee your bolts and fastenings retain maximum strength for as long as possible. nt.

Bolted Shut

Blind bolts are incredibly versatile and our customers are constantly surprising us with new ways of using them to save time and money. We meet this challenge by creating innovations of our own and increasing the sizes we offer to meet your demands.

Interested in finding out more about our blind bolts? Then feel free to get in touch and speak to a member of the Blind Bolt team today on (630)882-9010 or send us an email on enquiries@blindbolt.com. We look forward to hearing from you.

Blind Bolt