the

Thin Wall Bolt

The Thin Wall Bolt, known as the TW Bolt, was developed as a blind fixing which could be used in conjunction with cladding material or lightweight steel sheet.

Thin Wall Fasteners

The TW Bolt combines convenience with performance. Once the bolt is fitted, only a low profile head is visible with no stud, while the bolt itself boasts a high shear capacity.

Advantages of the TW Bolt:

- Quick and simple installation

- No requirement for an oversized hole

- Durability augmented by zinc electroplate finish

- Makes any assembly more efficient

We’re constantly developing new products and devising innovative applications. Please visit our expert guides page to learn more.

For detailed information on installation or removal, please view our Thin Wall Bolt Installation and removal guide TW Fitting Instructions.

If you have a specific project in mind, please get in touch using the contact details below. Our team are ready and waiting to explain exactly how Blind Bolts could help.

Thin Wall Bolt

Technical Data

NOTE: All dimensions are in mm or in inches as appropriate unless stated otherwise.

The Blind Bolt Company reserve the right to change these technical details without notice.

Thin Wall Bolt Product Specification

|

|||||

| Bolt Size | Hole | Depth | Clamping Range (mm) | ||

| (Stock Number) | Diameter (mm) | Clearance (mm) | Min | Max | |

| TW5ZF-10 | 8 | 35 | 2 | 10 | |

| 5⁄16" | 1 3⁄8" | 5⁄64" | 13⁄32" | ||

| TW5ZF-16 | 8 | 40 | 8 | 16 | |

| 5⁄16" | 1 9⁄16" | 5⁄16" | 5⁄8" | ||

| TW6ZF-10 | 10 | 35 | 2 | 10 | |

| 7⁄16" | 1 3⁄8" | 5⁄64" | 13⁄32" | ||

| TW6ZF-16 | 10 | 40 | 8 | 16 | |

| 7⁄16" | 1 9⁄16" | 5⁄16" | 5⁄8" | ||

| TW8ZF-10 | 13 | 35 | 8 | 16 | |

| 9⁄16" | 1 3⁄4" | 5⁄64" | 13⁄32" | ||

| TW8ZF-16 | 13 | 40 | 8 | 16 | |

| 9⁄16" | 2" | 5⁄16" | 5⁄8" | ||

Design Resistance for TW Type Blind Bolts

|

|||||||||

| TW Bolt Size | Tension Resistance | Shear Resistance | |||||||

| LRFD | ASD | LRFD | ASD | ||||||

| kN | KIPS | kN | KIPS | kN | KIPS | kN | KIPS | ||

| TW5 | 5.32 | 1.24 | 3.68 | 0.83 | 14.6 | 3.28 | 9.73 | 2.19 | |

| TW6 | 14.0 | 3.16 | 9.36 | 2.10 | 21.7 | 4.87 | 14.5 | 3.25 | |

| TW8 | 22.5 | 5.06 | 15.0 | 3.37 | 37.9 | 8.52 | 25.3 | 5.68 | |

Design resistances in shear and tension are presented above. The resistance values may be compared directly with the ultimate loads applied to the fixing.

The bearing resistance may be calculated in accordance with the design standard, based on the external diameter of the collar, as given above.

Fixings subject to combined shear and tension should be verified in accordance with the design standard, using the design resistances presented above.

If tension is applied to a fixing in a relatively thin wall application, the deformation of the connected material should be considered at serviceability (working loads) and at the ultimate limit state, as deformation is likely to be the limiting feature of the connection.

Thin Wall Bolt Product Specification

|

|||||

| Bolt Size | Hole | Depth | Clamping Range (mm) | ||

| (Stock Number) | Diameter (mm) | Clearance (mm) | Min | Max | |

| TW5SS-10 | 8 | 35 | 2 | 10 | |

| 5⁄16" | 1 3⁄8" | 5⁄64" | 13⁄32" | ||

| TW5SS-16 | 8 | 40 | 8 | 16 | |

| 5⁄16" | 1 9⁄16" | 5⁄16" | 5⁄8" | ||

| TW6SS-10 | 10 | 35 | 2 | 10 | |

| 7⁄16" | 1 3⁄8" | 5⁄64" | 13⁄32" | ||

| TW6SS-16 | 10 | 40 | 8 | 16 | |

| 7⁄16" | 1 9⁄16" | 5⁄16" | 5⁄8" | ||

| TW8SS-10 | 13 | 35 | 8 | 16 | |

| 9⁄16" | 1 3⁄4" | 5⁄64" | 13⁄32" | ||

| TW8SS-16 | 13 | 40 | 8 | 16 | |

| 9⁄16" | 2" | 5⁄16" | 5⁄8" | ||

Design Resistance for TW Type Blind Bolts

|

|||||||||

| TW Bolt Size | Tension Resistance | Shear Resistance | |||||||

| LRFD | ASD | LRFD | ASD | ||||||

| kN | KIPS | kN | KIPS | kN | KIPS | kN | KIPS | ||

| TW5 | 6.15 | 1.38 | 4.1 | 0.92 | 12.5 | 2.82 | 8.36 | 1.88 | |

| TW6 | 10.5 | 2.36 | 7.0 | 1.57 | 18.7 | 4.21 | 12.5 | 2.80 | |

| TW8 | 18.2 | 4.08 | 12.1 | 2.72 | 32.6 | 7.34 | 21.8 | 4.89 | |

Design resistances in shear and tension are presented above. The resistance values may be compared directly with the ultimate loads applied to the fixing.

The bearing resistance may be calculated in accordance with the design standard, based on the external diameter of the collar, as given above.

Fixings subject to combined shear and tension should be verified in accordance with the design standard, using the design resistances presented above.

If tension is applied to a fixing in a relatively thin wall application, the deformation of the connected material should be considered at serviceability (working loads) and at the ultimate limit state, as deformation is likely to be the limiting feature of the connection.

Thin Wall Bolt

Fixing Data Explained

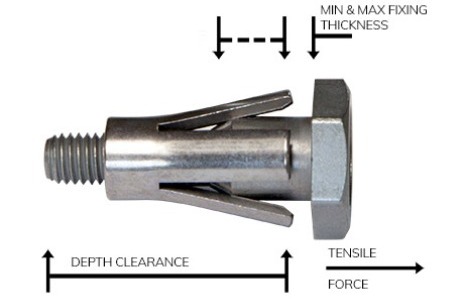

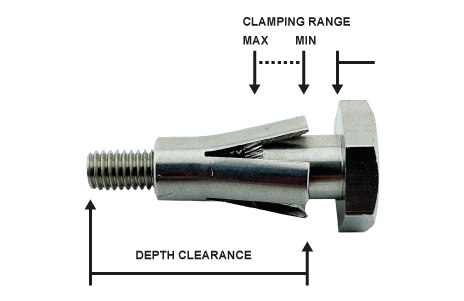

The unique and innovative design of the TW Bolt means that certain specific criteria need to be met in order for it to be applied successfully.

Using these criteria means being aware of the way in which the dimensions of each thin wall bolt are measured from the testing data, and these details are set out below.

The image above also offers a pictorial representation of each term.

If you still have any questions about the testing data, please get in touch with us using the contact details at the bottom of the page or by sending us an email by clicking here.

Thin Wall Bolt

Fitting Instructions

Installations & Removal Videos

The following videos visually represents the detailed installation of the Thin Wall Bolt.