the

Heavy Duty Bolt

The Heavy Duty Bolt, known as the HD Bolt, was developed as a shorter blind fixing which would offer improved performance when the shear plane being fixed falls across the legs of a standard Blind Bolt

The HD Bolt represents the optimum fixing solution when dealing with heavy weight steel sections. The unique pin locking mechanism and expanding base combine strength with a simple activation process. The only tools necessary are a hammer and spanner, rather than the specialist equipment required when using alternative products. This means that using the Heavy Duty Bolt saves on installation time and expense.

Advantages of the HD Bolt:

- Quick and simple installation

- No requirement for an oversized hole

- 1000 hours of salt spray protection provided by Zinc Flake 1000Hr SSP coating

- Makes any assembly more efficient

- Unique pin locking facility

We’re constantly developing new products and devising innovative applications. Please visit our experts guide page to learn more. If you have a specific project in mind, please get in touch using the contact details below. Our team are ready and waiting to explain exactly how Blind Bolts could help.

For detailed information on installation, please view our Heavy Duty Bolt Installation guide, Heavy Duty Bolt Fitting Instructions.

HEAVY DUTY BOLT

Technical Details

NOTE: All dimensions are in inches unless stated otherwise.

The Blind Bolt Company reserve the right to change these technical details without notice.

Heavy Duty Product Specification High Tensile Steel |

|||||||

| Thread Size |

Hole Size (As close to hole size as possible) |

Product Code |

Qty Box |

Socket Size |

Fixing Thickness |

Weight Per Box (lbs) |

|

| Min |

Max | ||||||

| 1/2 - 13 UNC | .500 | HDS-5000-2.40 | 20 | 3/4 | 0.200 | 1.38 | 2.44 |

| 5/8 - 11 UNC | .6250 | HDS-6250-3.00 | 20 | 15/16 | 0.200 | 1.38 | 5.78 |

| 3/4 - 10 UNC | .7500 | HDS-7500-3.40 | 10 | 1-1/8 | 0.200 | 1.38 | 5.18 |

Heavy Duty Performance Data High Tensile Steel - 50,000 PSI Tensile Strength |

|||||

| Thread Size | Product Code | Stress Area (IN2) |

Bolt Steel Grade | Ultimate Tensile Strength (LBF) |

Ultimate Shear Strength (LBF) |

| 1/2 - 13 UNC | 1/2 - 13 UNC | .141 | High Tensile Steel | 7000 | 7500 |

| 5/8 - 11 UNC | 5/8 - 11 UNC | .226 | High Tensile Steel | 8000 | 12000 |

| 3/4 - 10 UNC | 3/4 - 10 UNC | .334 | High Tensile Steel | 14000 | 18000 |

HEAVY DUTY BOLT

Testing Data Explained

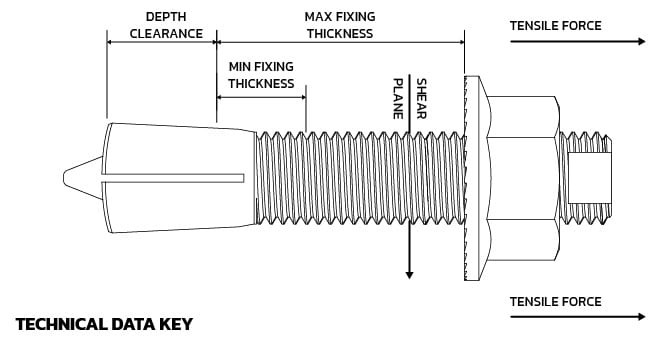

The unique and innovative design of the HD Bolt means that certain specific criteria need to be met in order for it to be applied successfully.

Using these criteria means being aware of the way in which the dimensions of each bolt are measured, and these details are set out below.

The image above also offers a pictorial representation of each term. If you still have any questions, please get in touch with us using the contact details at the bottom of the page or by sending us an email by clicking here.

HEAVY DUTY BOLT

Fitting Instructions

The following videos visually represents the detailed installation of the Heavy Duty Bolt.

HD Bolt Installation Instruction