4 Types of Fasteners Used for Thin-Walled Joints

Blind Bolt US | 6th April 2021

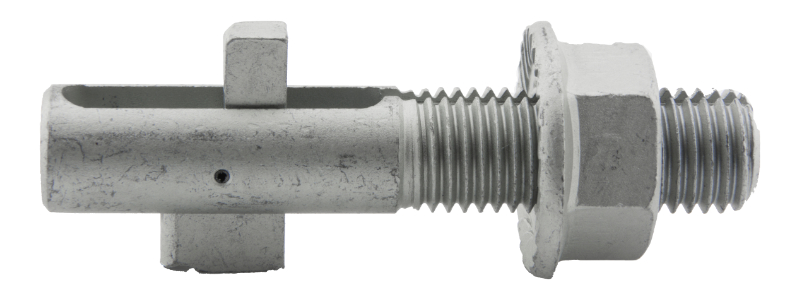

Thin Wall Bolt

There are four main types of fasteners that can be used when working with thin-walled joints. These include tapping screws, blind rivets, conventional rivets and thin wall bolts. Each type of fastener has its own unique assets and uses.

Thin Wall Bolts

Thin wall bolts are also sometimes known as TW bolts. They were specifically designed to deal with the problem of needing a quality blind fixing when attaching material such as cladding or lightweight steel sheet. Using a TW means that after the material has been installed there is no stud showing, just a small, barely visible head.

The other benefits of using a thin wall bolt include the fact that it offers extremely strong capacity despite being quick and simple to install. The fact that it doesn’t need a large hole to deliver maximum performance means that TW bolts can be used without impacting the appearance of the materials being attached. The finish of a thin wall bolt consists of a zinc electroplate which provides first rate protection and the peace of mind of knowing that anything they hold in place is held in place extremely securely.

Tapping Screws

Tapping screws are the ideal choice for large scale projects because they work equally well across a wide range of materials in different thicknesses. The materials they can be used with include zinc, aluminum, brass, bronze, structural steel and even wood, as long as the thickness of the material falls between 0.03 and 0.50 inches, although it should be noted that tapping screws are often more expensive than alternatives such as rivets.

Tapping screws can be installed manually or with the use of power tools, but in both cases the installation process tends to take up a lot of time. This is particularly true when high driving torques are needed for harder materials like stainless steel.

Blind Rivets

The Blind Bolt has gone from being an innovative blind fixing offering something new, to being a fastener which is used in great numbers across the construction industry. The advantage of a constantly evolving construction sector is that it enables designers and architects to consider new ways of working, and the blind bolt is an excellent example of this phenomenon.

It has removed the difficulty normally associated with fixing into a box section or girder cavity, offering a dependable solution which also cuts costs. Already, the blind bolt has helped to transform the construction industry, and its incredible potential is still to be fully explored.

Conventional Rivets

Conventional rivets come in a broad range of types, sizes and materials. No matter what your particular thin wall joint requirements are, you’re bound to be able to find a conventional rivet that can handle the job, from tubular to bifurcated.

The high level of vibration resistance offered by conventional rivets is definitely a bonus, but it does tend to mean that disassembly and reassembly are difficult and lengthy processes. Another downside of conventional rivets is that access to the back of the joint is required during installation, which means having to drill an aesthetically unappealing access hole.

Bolted Shut

Would thin wall bolts provide the fastening solution you need? Get in touch and speak to a member of the BlindBolt team today by using the contact form below to find out more about our thin wall bolts and how they can benefit your project. Alternatively, you can contact a member of our team on (630)882-9010 or by email at enquiries@blindbolt.com. We look forward to hearing from you.

Blind Bolt